|

||

|

In this article I will explain how I hacked into my car harness in order to read current RPM. This approach is not universal and there are no guarantees - this article only

applies to my car and you should not attempt doing anything like that to yours.

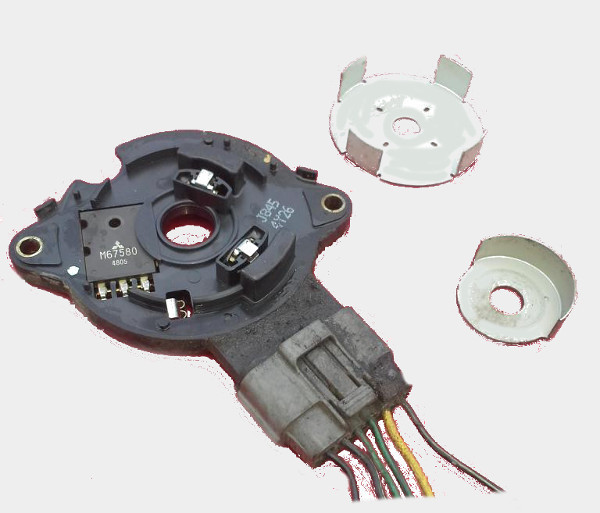

A bit of technical background first: the car I have hacked was sold in US as Ford Aspire, it was made in South Korea and it's Mazda design with some Mitsubishi components. Not your average F150 exactly :) This car uses Hall effect crankshaft position sensors (no idea how that works). So I could have used the same approach for something like Mazda Protege or even a Miata from the 90's - the younger cars would have sensors based on Variable reluctance and that would be a different story. When I open the hood, I see a distributor like the one on the picture

If I would have decided to break this distributor and look inside, I would see something like

That tin wheel spins with the crankshaft and that's what make the CKP signal. If I would keep taking it apart, I would see the actual sensors and the other wheel - the smaller wheel is in charge of CID signal.

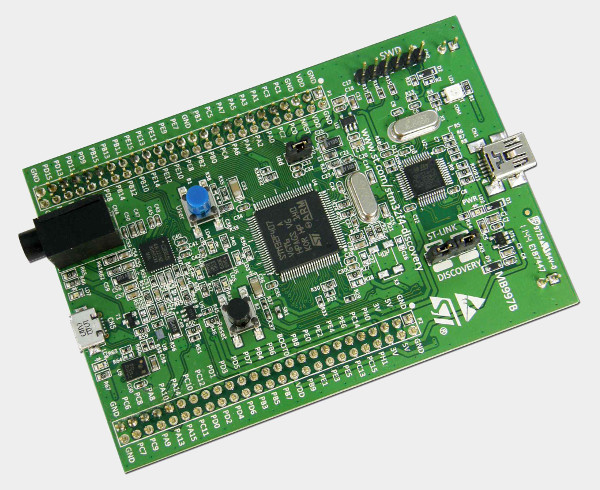

Does not really matter what CKP and CID signals are. We only care that even while the car has a 12 volts battery, most of the sensors and the stock ECU run on 5 volts. Somewhere in my harness where are two 5 volts wave signals which look like this:  That's it. We can wire this signal right into the any 5v tolerant microcontroller. Just to be a bit safer, we will put a 1n4001 diode between the harness and the microcontroller. So, let's get something done. Let's take a STM32F4DISCOVERY dev board - that's a $15 board based on some stm32f4 microcontroller running at 168MHz.  That's actually a lot of cheap computation power. As is, microcontrollers are not exactly super friendly - ChibiOS/RT would help us, we will let it take care of the the lower level. We will use serial-over-usb to output data - so, mini-usb cable would be used to flash & power the board and the micro-usb cable would be used for serial. If you made it to here you probably know what serial is. It's not much code, it's quite self-explanatory:

It really isn't that hard, right? Want to join the fun? Here is the whole project source: tachometer.zip |

Comments?