Page 1 of 1

minEFI

Posted: Sun Jul 26, 2015 12:04 pm

by rus084

i will make small ecu board .

i deleted all no needed for me from frankenso and get something about this:

1.png

NOW:

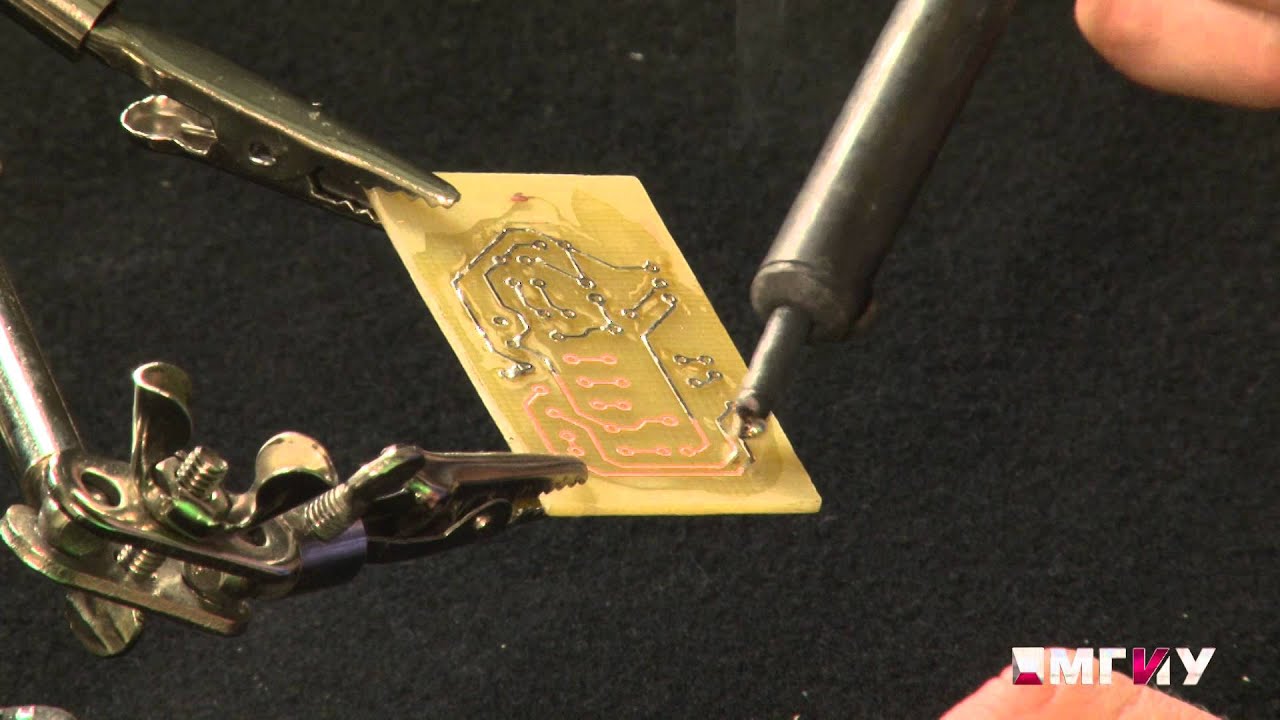

2.png

im learning KIKAD and want to make board better .

if you want i can upload sources .

Re: minEFI

Posted: Sun Jul 26, 2015 12:22 pm

by AndreyB

Please upload the sources for people to provide feedback!

Re: minEFI

Posted: Sun Jul 26, 2015 1:12 pm

by rus084

ok

don't swear me , im still learning KICAD

Re: minEFI

Posted: Sun Jul 26, 2015 3:13 pm

by kb1gtt

Good to see you making the attempt. I'm a bit busy for the next month or so. I'll try to review but have limited time right now. Keep up the good work.

Re: minEFI

Posted: Sun Jul 26, 2015 4:45 pm

by rus084

thanks

Re: minEFI

Posted: Tue Jul 28, 2015 9:23 am

by kb1gtt

Some suggestions.

rename frankenso.sch to miniefi.sch

rename frankenso.cmp to miniefi.cmp

rename first.kicad_pcb to miniefi.kicad_pcb

rename frankenso.net to miniefi.net

These changes will make the KICAD project manager play nice and allow you KICAD's interconnecting linking to work correctly.

Remove .kicad_pcb.kicad_pcb, first.pro and frankenso-cache.lib

Those files are not needed might as well clean them out as they serve no purpose. KICAD will probably re-make the blah-cache.lib file, but will re-make it as miniefi-cache.lib.

update known_issues.txt to include the content in your files.

The switch mode caps are reasonably tall, they will be a problem for you STM board.

In the schematic, run the ERC (button looks like a bug)

In the PCB layout, run the DRC (button looks like a bug)

Add copper floods and via's near and under the low side driver chips. Those chips have a reasonably poor thermal resistance to a heat sink, you need more copper to help get the heat out of the chips.

Add more copper and vias around the LM2596 again thermal issue.

Re: minEFI

Posted: Tue Jul 28, 2015 2:17 pm

by rus084

i have problem with KICAD for windows (i don't see half of schematic)

on linux KICAD work's excellent .

i see errors in schematic but don't know how to fix some of them .

i move switch caps

Re: minEFI

Posted: Tue Jul 28, 2015 5:11 pm

by rus084

here is current version of files

https://github.com/rus084/minefi

DRC wrote what pins on max9926 is too near

i dont know how to add vias and copper flood .

Re: minEFI

Posted: Wed Jul 29, 2015 12:14 am

by kb1gtt

MAX pins are something like 7.1mils spacing. In PCBNew --> Design Rules --> Design Rules --> Net Class Editor, then change the clearance to .007. Your first posted files had that set to .010 while the MAX needs something like .007.

Lots of videos out there about how to add vias and floods. Short version is to press the "v" key for a via while you are laying down a copper trace. It will punch through to the other side, then start routing on that other side. If you hit "v" again it will punch a via through to the front. Floods (fill zones) are an option over on the right side. Also KICAD has about the only help file I've ever found helpful. Try a search the help and see if that sheds some light on the topic.

Re: minEFI

Posted: Wed Jul 29, 2015 6:42 pm

by rus084

DRC wrote "no errors"

do you mean this copper floods and vias?

Re: minEFI

Posted: Wed Jul 29, 2015 10:08 pm

by kb1gtt

Yes, and it's good practice to flood all extra area with GND copper.

Re: minEFI

Posted: Thu Jul 30, 2015 1:36 am

by abecedarian

kb1gtt wrote:Yes, and it's good practice to flood all extra area with GND copper.

Also, usually a good idea to keep digital grounds separated from analog grounds, and both separated from power supply grounds... but tie them all together in one place.

Re: minEFI

Posted: Thu Jul 30, 2015 3:17 am

by kb1gtt

Also a good idea to not have digital GND and analog GND. You should separate your GND's by controlling the current loops that the traces make not by physical barriers in your GND planes. See this article for some extra details on some basic routing guide lines and gut feel data points.

http://www.maximintegrated.com/en/app-notes/index.mvp/id/5450

Re: minEFI

Posted: Thu Jul 30, 2015 10:08 am

by rus084

maybe just need to make better ground ?

Re: minEFI

Posted: Thu Jul 30, 2015 11:13 pm

by abecedarian

kb1gtt wrote:Also a good idea to not have digital GND and analog GND. You should separate your GND's by controlling the current loops that the traces make not by physical barriers in your GND planes. See this article for some extra details on some basic routing guide lines and gut feel data points.

http://www.maximintegrated.com/en/app-notes/index.mvp/id/5450

I don't think I've ever been more confused by anything more than I'm confused now.

Traces = physical barriers between signals. So, contradictory information has been presented in a singular post.

*edit- Jared, I think you forgot to include the frequency component.

Re: minEFI

Posted: Fri Jul 31, 2015 9:55 am

by kb1gtt

There is some benefit of using different net names for your Vbat negative signals. This probably doesn't make sense to rus084 right now, but here's a note about it any how. Also please note I do not bother with this possibility as it adds compilations that can bugger the layout by miss leading you.

For example your injectors will pass about 1 amp, while your analog will pass milli amps. This means your analog will typically want the smallest trace possible, and your injectors will want a trace width wider than 30mils as noted from this tool

http://circuitcalculator.com/wordpress/2006/01/31/pcb-trace-width-calculator/ or as noted from this tool

http://www.saturnpcb.com/pcb_toolkit.htm PCBNew's In PCBNew you can use "design rules" to check that you have the proper width for your traces. If you establish an "injector_negative" net name and an "AGND" net name in your schematic, then in PCBNew you set your design rules to different specific widths, you can get some help from DRC to ensure you don't forget to set the trace widths properly. See below graphic which shows how they used different GND symbols but they are all connected.

http://e2e.ti.com/cfs-file/__key/communityserver-discussions-components-files/166/3010.gnd.png

What I do for the GND signals is use one GND net name in the schematic and set the PCBNew DRC to the min widths. Then when laying out the copper I manually change the width to wider widths to ensure the traces are fat enough for the current that is expected to pass through the trace. I do this because the widths on the outer layers vs internal layers are different. Typically your stack up is 1 ozcu outer and .5 ozcu inners. As well the inners are thermally insulated. Which means when you use a via to change from an innner layer to an outer layer you have the same net name, but need 2 different trace widths. Rather then trying to get the software to keep track of it, I just do that manually. I haven't see a PCB tool yet that will do this automatic stuff correctly yet, which is why I like KICAD. I don't have to turn off all sorts of automatic stuff before I can get it to behave properly. It just behaves properly from initial install.

Re: minEFI

Posted: Fri Jul 31, 2015 5:02 pm

by abecedarian

Maybe that's "my" issue: I'm not using Kicad. It's still too f'd up to make sense, as in why run 3-4 different programs just to get something going.

Anyhow, I can name all my ground nets "GND" and only get air wires shown to connect them.

Re: minEFI

Posted: Fri Aug 07, 2015 8:16 pm

by rus084

i dont know english word mean's this

it's a good idea for power wires?

Re: minEFI

Posted: Sat Aug 08, 2015 8:43 pm

by kb1gtt

That created lots of stress in the traces which commonly results in long term issues. I would suggest wider traces if you can.

Re: minEFI

Posted: Sat Aug 08, 2015 9:14 pm

by rus084

i can make wider wires if you want

Re: minEFI

Posted: Tue Sep 01, 2015 11:59 am

by rus084

changed vr input to lm1815 and use different connectors for modules .

Re: minEFI

Posted: Sat Oct 31, 2015 12:42 pm

by RasPL

Just now i've founded this thread. Maybe for this minimalistic rusefi motherboard is better to use MC33810 4channel ignition/injector driver ?

http://www.freescale.com/files/analog/doc/data_sheet/MC33810.pdf

Re: minEFI

Posted: Sat Oct 31, 2015 9:23 pm

by kb1gtt

I believe part of the effort is to make this easily obtained in the remote foot hills of Russia. These specialty chips are not common there. The MC33812 includes 4 channels of injection, as well as 4 channels of IGBT drivers, all in one chip.

http://www.freescale.com/files/analog/doc/data_sheet/MC33812.pdf

Re: minEFI

Posted: Fri Nov 06, 2015 6:26 pm

by abecedarian

kb1gtt wrote:I believe part of the effort is to make this easily obtained in the remote foot hills of Russia. These specialty chips are not common there. The MC33812 includes 4 channels of injection, as well as 4 channels of IGBT drivers, all in one chip.

http://www.freescale.com/files/analog/doc/data_sheet/MC33812.pdf

MC33810 is the correct chip for 4 inj +4 ign drivers. Worth noting it's compatible with both 3v3 and 5v0 MCUs.

MC33812 is a small engine IC for 1/2 cylinders: 1 injector driver, one ignition pre-driver, one lamp and one relay driver.

Re: minEFI

Posted: Fri Nov 06, 2015 7:45 pm

by RasPL

Thats true. And main advantage of this chip is that You have all in one together with fault protection and diagnostics.

Re: minEFI

Posted: Sat Nov 07, 2015 3:58 pm

by abecedarian

RasPL wrote:Thats true. And main advantage of this chip is that You have all in one together with fault protection and diagnostics.

... If you choose to use them.

MC33812 is protected as well, despite its cylinder restrictions, which result in requiring batch fired injection and wasted spark ignition. However, MC33814 is a more robust option for a small engine since it provides independent control for 2 injector, 2 ignition, heated exhaust gas oxygen sensor heater control, and a VR sensor conditioner in a smaller package. Pair two of those and you have what essentially works out to be a 33810 plus support for 2 VR sensors, 2 O2 heaters, and 4 relays, with diagnostics amongst other things.

Anyways, I digress.

Re: minEFI

Posted: Thu Mar 01, 2018 6:47 am

by rus084

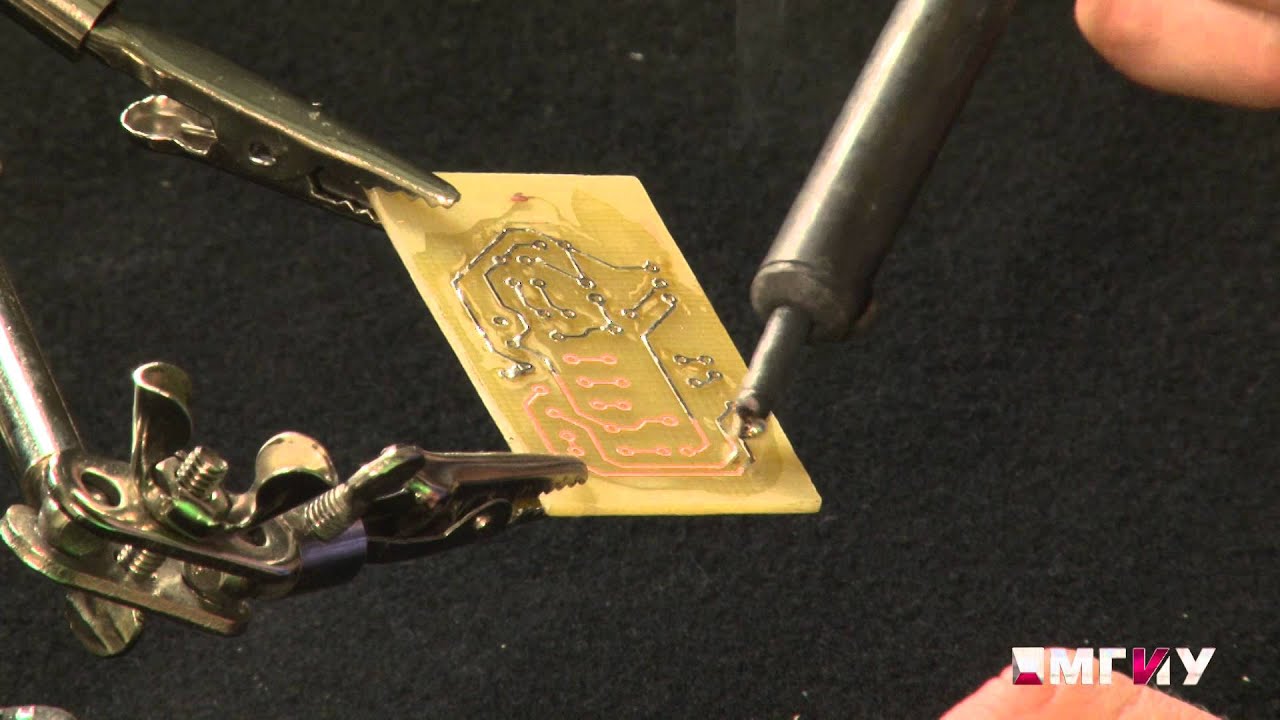

have some progress

minefi.png