#include <high_pressure_fuel_pump.h>

Public Member Functions | |

| angle_t | pumpAngleFuel (float rpm, HpfpController *model) |

| float | calcFuelPercent (float rpm) |

| float | calcPI (float rpm, float calc_fuel_percent, HpfpController *model) |

Detailed Description

Definition at line 38 of file high_pressure_fuel_pump.h.

Member Function Documentation

◆ calcFuelPercent()

Calculate the percent of the pump stroke needed to replace the fuel injected. Also includes pump compensation calculations.

This is used by internal tests and shouldn't be called directly. Instead use pumpAngleFuel.

Return value is nominally 0-100, but may be outside that range (including negative) if model parameters are not accurate.

Definition at line 78 of file high_pressure_fuel_pump.cpp.

Referenced by pumpAngleFuel().

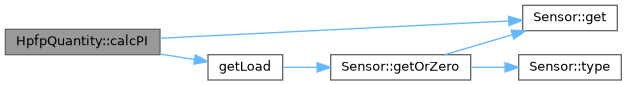

◆ calcPI()

| float HpfpQuantity::calcPI | ( | float | rpm, |

| float | calc_fuel_percent, | ||

| HpfpController * | model | ||

| ) |

Calculates the PI controller contribution as a percent. This amount should be added to calcFuelPercent() above.

This is used by internal tests and shouldn't be called directly. Instead use pumpAngleFuel.

Return value is nominally 0-100, but may be outside that range (including negative) if model parameters are not accurate. The sum of this and calc_fuel_percent will be 0-100.

Definition at line 99 of file high_pressure_fuel_pump.cpp.

Referenced by pumpAngleFuel().

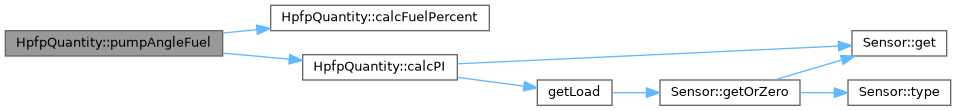

◆ pumpAngleFuel()

| angle_t HpfpQuantity::pumpAngleFuel | ( | float | rpm, |

| HpfpController * | model | ||

| ) |

Calculate where the pump should become active, in degrees before pump lobe TDC

Definition at line 139 of file high_pressure_fuel_pump.cpp.

Referenced by HpfpController::onFastCallback().

The documentation for this class was generated from the following files:

- controllers/engine_cycle/high_pressure_fuel_pump.h

- controllers/engine_cycle/high_pressure_fuel_pump.cpp