Detailed Description

set engine_type 49 FRANKENSO_QA_ENGINE See also DEFAULT_ENGINE_TYPE Frankenso QA 12 cylinder engine

- Date

- Jan 18, 2015

Definition in file custom_engine.cpp.

Functions | |

| void | setDiscoveryPdm () |

| void | setDiscovery33810Test () |

| void | setFrankensoConfiguration () |

| void | setEtbTestConfiguration () |

| void | setEepromTestConfiguration () |

| void | setL9779TestConfiguration () |

| void | proteusDcWastegateTest () |

| static void | setBasicNotECUmode () |

| void | setBodyControlUnit () |

| void | mreSecondaryCan () |

| void | mreBCM () |

| void | setBoschHDEV_5_injectors () |

| void | setRotary () |

| void | setTest33816EngineConfiguration () |

| void | proteusLuaDemo () |

| void | detectBoardType () |

| void | fuelBenchMode () |

| void | proteusStimQc () |

| void | testEngine6451 () |

Variables | |

| static uint8_t | write_buf [EE_PAGE_SIZE+10] |

| static const I2CEepromFileConfig | i2cee |

| EepromDevice | eepdev_24xx |

| static I2CEepromFileStream | ifile |

Function Documentation

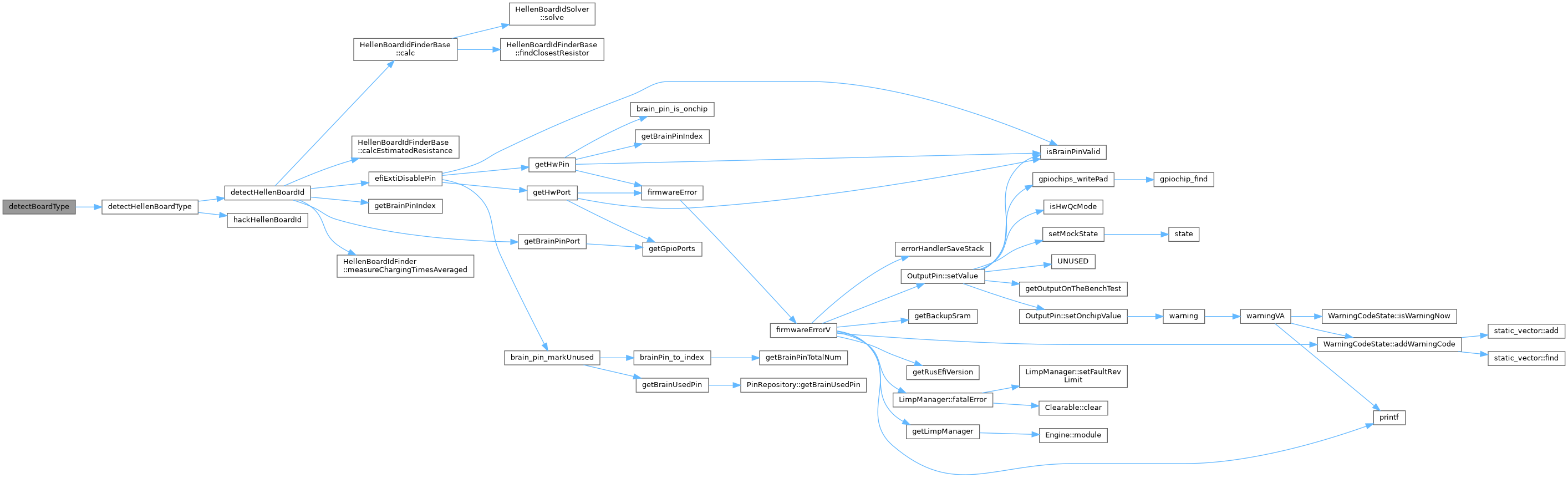

◆ detectBoardType()

| void detectBoardType | ( | ) |

Definition at line 612 of file custom_engine.cpp.

Referenced by runRusEfi().

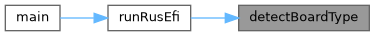

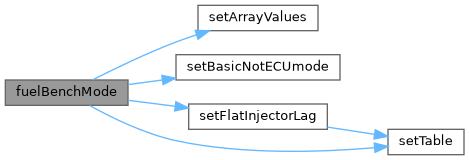

◆ fuelBenchMode()

| void fuelBenchMode | ( | ) |

Definition at line 621 of file custom_engine.cpp.

Referenced by applyEngineType().

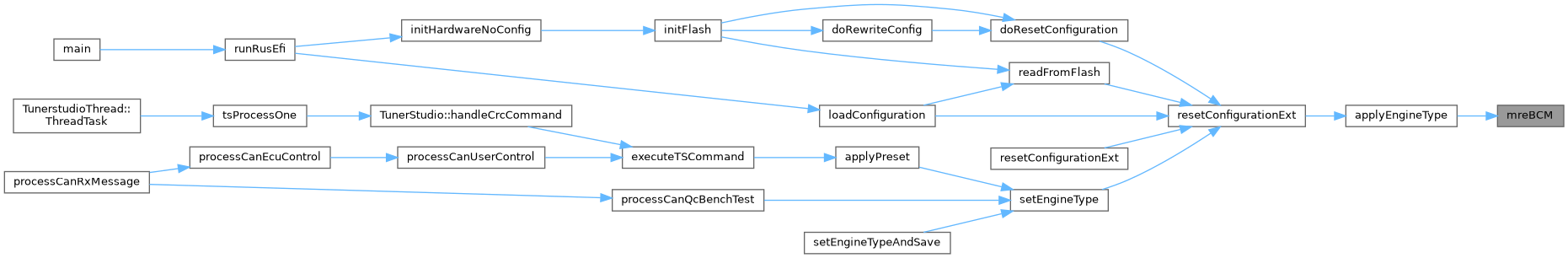

◆ mreBCM()

| void mreBCM | ( | ) |

Definition at line 381 of file custom_engine.cpp.

Referenced by applyEngineType().

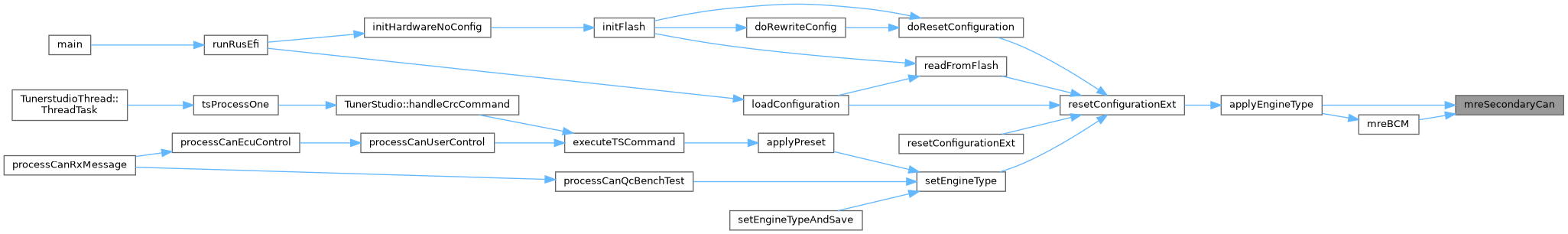

◆ mreSecondaryCan()

| void mreSecondaryCan | ( | ) |

Definition at line 344 of file custom_engine.cpp.

Referenced by applyEngineType(), and mreBCM().

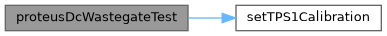

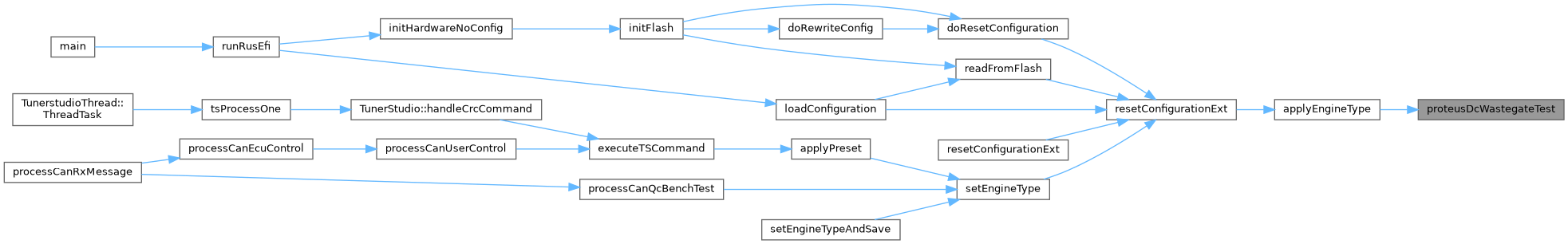

◆ proteusDcWastegateTest()

| void proteusDcWastegateTest | ( | ) |

Definition at line 286 of file custom_engine.cpp.

Referenced by applyEngineType().

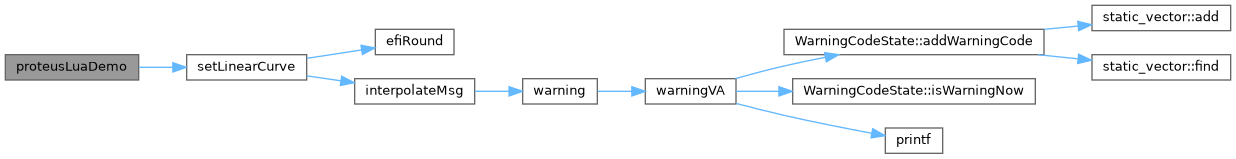

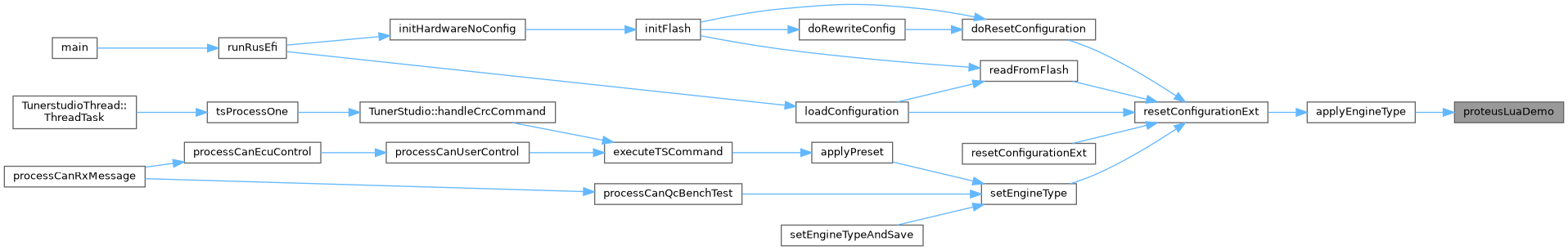

◆ proteusLuaDemo()

| void proteusLuaDemo | ( | ) |

for this demo I use ETB just a sample object to control with PID. No reasonable person should consider actually using Lua for actual intake ETB control while driving around the racing track - hard-coded ETB control is way smarter!

controlIndex = 0 directionIndex = 1

print('pid output ' .. output) print('')

local duty = (bias + output) / 100

– isPositive = duty > 0; – pwmValue = isPositive and duty or -duty – setPwmDuty(controlIndex, pwmValue)

– dirValue = isPositive and 1 or 0; – setPwmDuty(directionIndex, dirValue)

– print('pwm ' .. pwmValue .. ' dir ' .. dirValue)

Definition at line 489 of file custom_engine.cpp.

Referenced by applyEngineType().

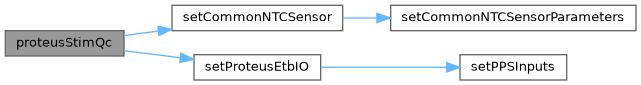

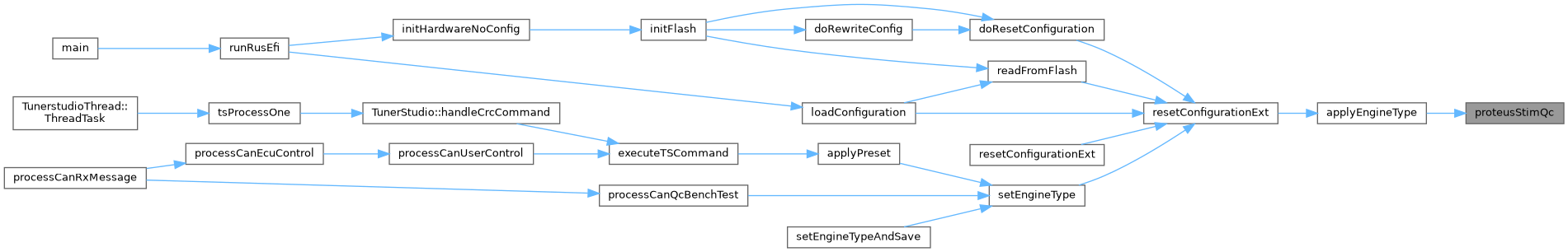

◆ proteusStimQc()

| void proteusStimQc | ( | ) |

Definition at line 635 of file custom_engine.cpp.

Referenced by applyEngineType().

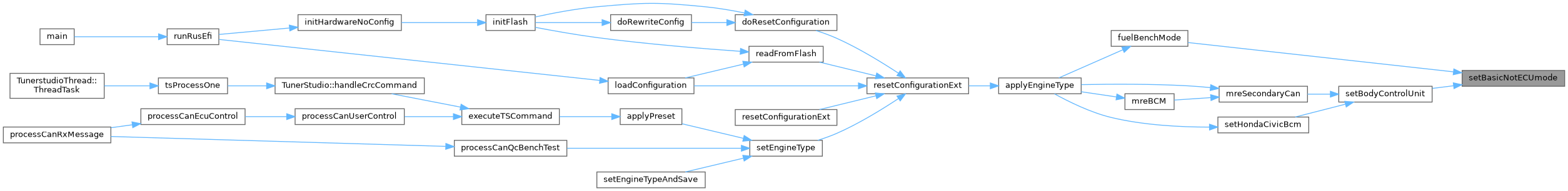

◆ setBasicNotECUmode()

|

static |

Definition at line 315 of file custom_engine.cpp.

Referenced by fuelBenchMode(), and setBodyControlUnit().

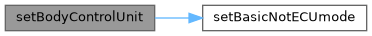

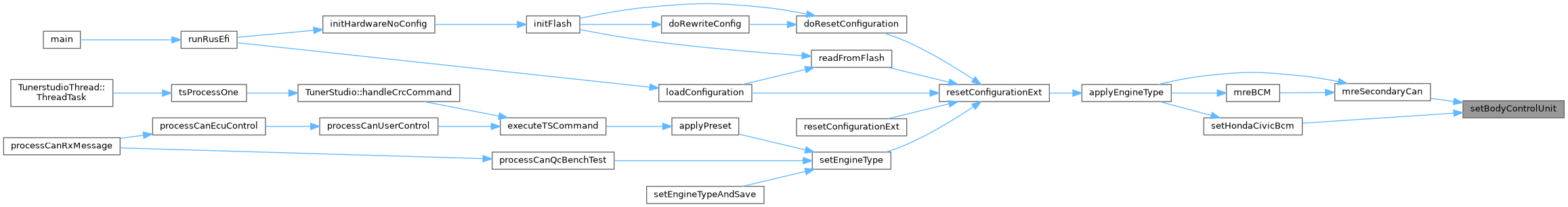

◆ setBodyControlUnit()

| void setBodyControlUnit | ( | ) |

Definition at line 336 of file custom_engine.cpp.

Referenced by mreSecondaryCan(), and setHondaCivicBcm().

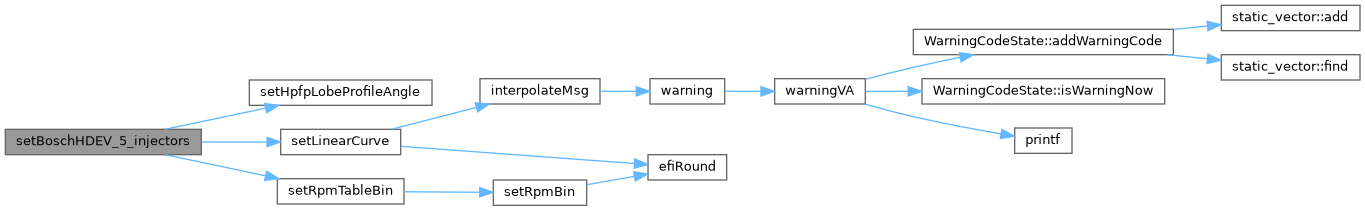

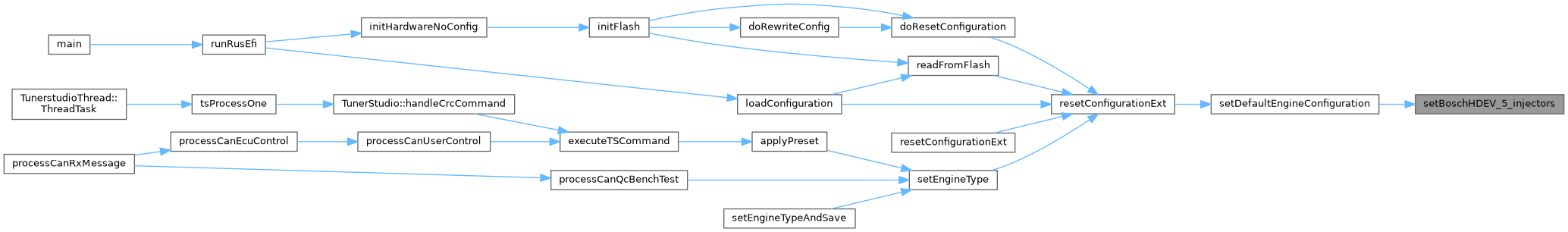

◆ setBoschHDEV_5_injectors()

| void setBoschHDEV_5_injectors | ( | ) |

Definition at line 387 of file custom_engine.cpp.

Referenced by setDefaultEngineConfiguration().

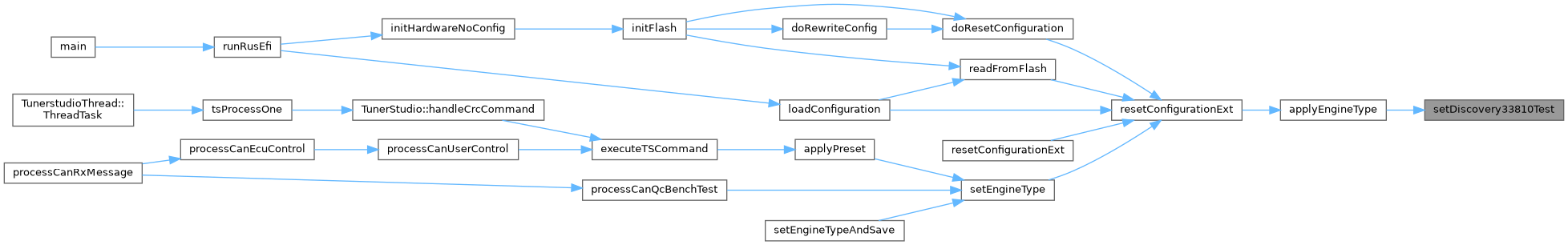

◆ setDiscovery33810Test()

| void setDiscovery33810Test | ( | ) |

set engine_type 59

Definition at line 43 of file custom_engine.cpp.

Referenced by applyEngineType().

◆ setDiscoveryPdm()

| void setDiscoveryPdm | ( | ) |

Definition at line 35 of file custom_engine.cpp.

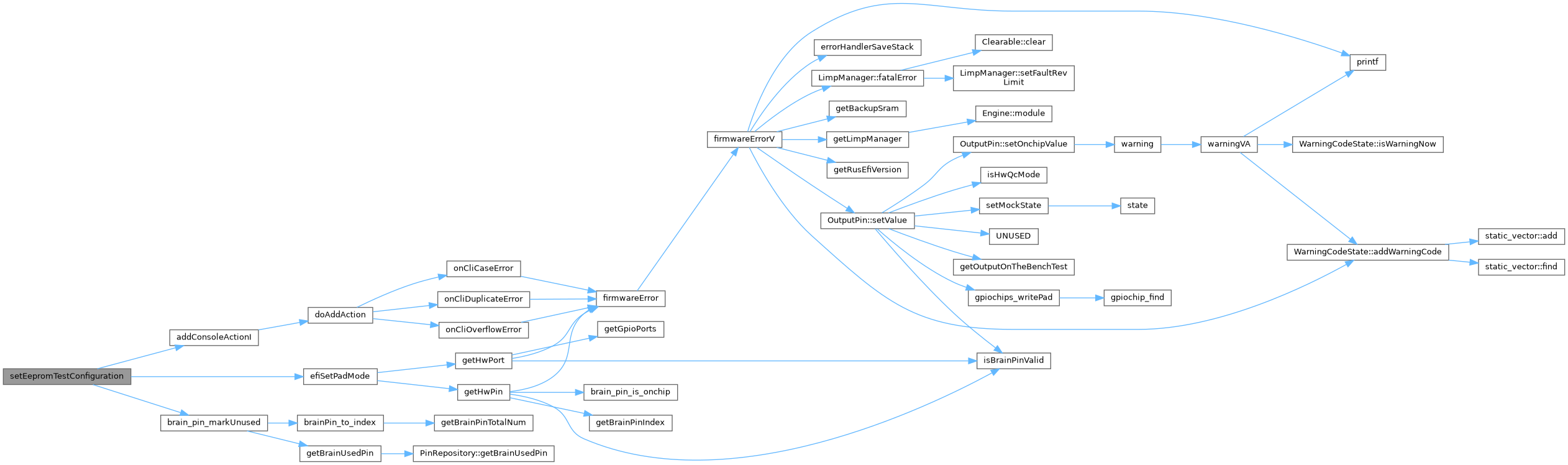

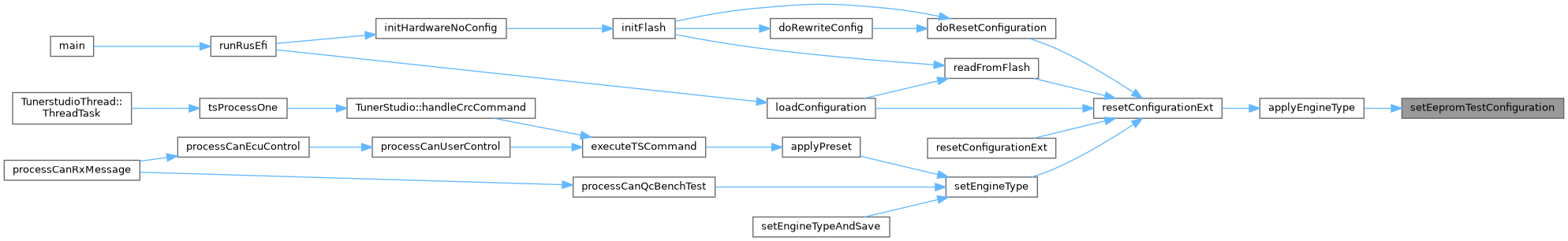

◆ setEepromTestConfiguration()

| void setEepromTestConfiguration | ( | ) |

set engine_type 61

Definition at line 234 of file custom_engine.cpp.

Referenced by applyEngineType().

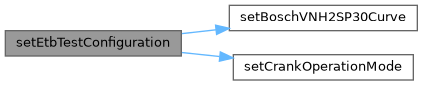

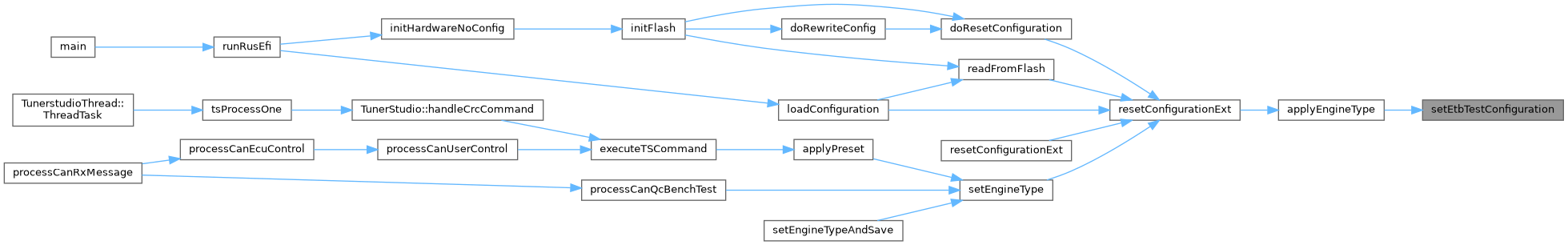

◆ setEtbTestConfiguration()

| void setEtbTestConfiguration | ( | ) |

remember that some H-bridges require 5v control lines, not just 3v logic outputs we have on stm32

Definition at line 160 of file custom_engine.cpp.

Referenced by applyEngineType().

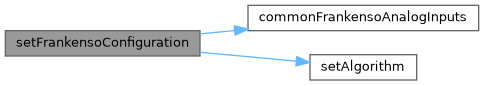

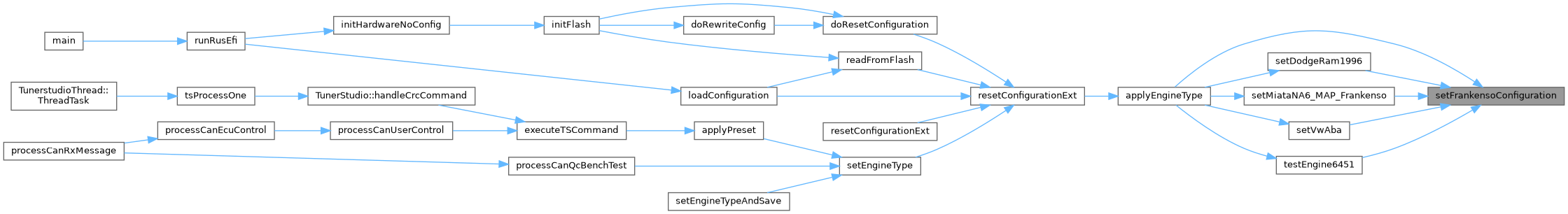

◆ setFrankensoConfiguration()

| void setFrankensoConfiguration | ( | ) |

Frankenso analog #1 PC2 ADC12 CLT Frankenso analog #2 PC1 ADC11 IAT Frankenso analog #3 PA0 ADC0 MAP Frankenso analog #4 PC3 ADC13 WBO / O2 Frankenso analog #5 PA2 ADC2 TPS Frankenso analog #6 PA1 ADC1 Frankenso analog #7 PA4 ADC4 Frankenso analog #8 PA3 ADC3 Frankenso analog #9 PA7 ADC7 Frankenso analog #10 PA6 ADC6 Frankenso analog #11 PC5 ADC15 Frankenso analog #12 PC4 ADC14 VBatt

http://rusefi.com/wiki/index.php?title=Manual:Hardware_Frankenso_board

Definition at line 73 of file custom_engine.cpp.

Referenced by applyEngineType(), setDodgeRam1996(), setMiataNA6_MAP_Frankenso(), setVwAba(), and testEngine6451().

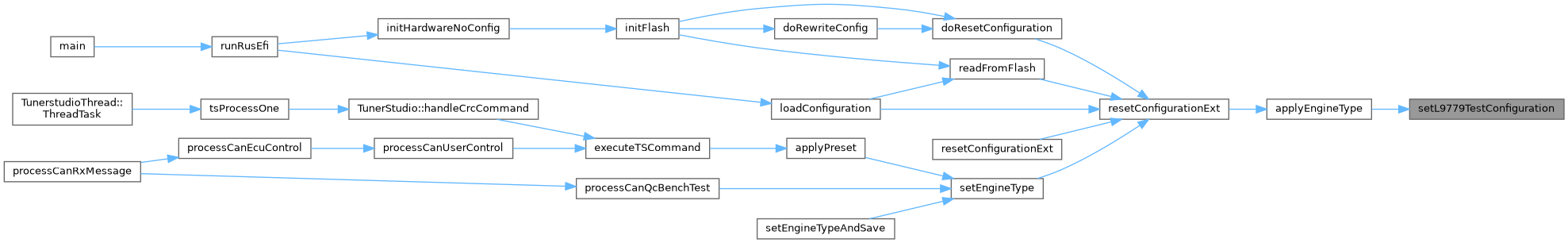

◆ setL9779TestConfiguration()

| void setL9779TestConfiguration | ( | ) |

Definition at line 265 of file custom_engine.cpp.

Referenced by applyEngineType().

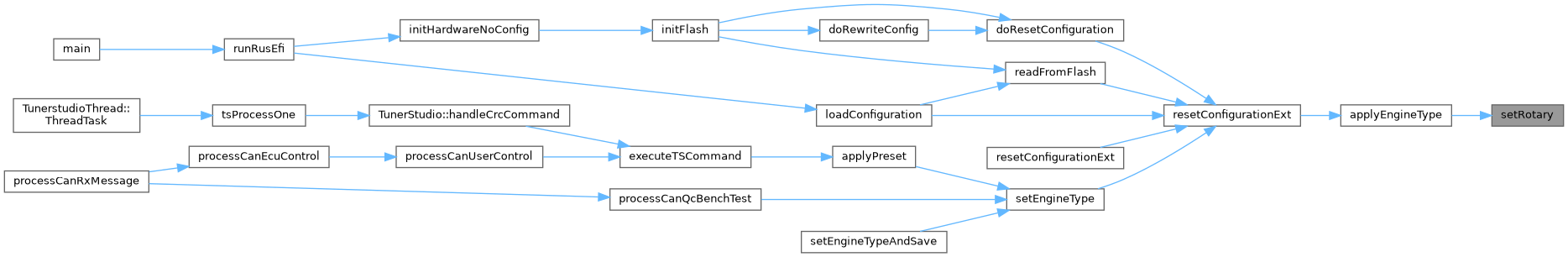

◆ setRotary()

| void setRotary | ( | ) |

set engine_type 107

Definition at line 425 of file custom_engine.cpp.

Referenced by applyEngineType().

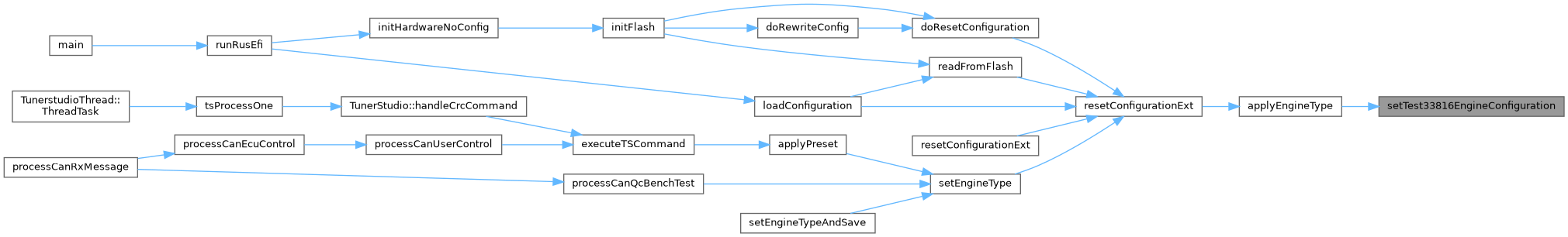

◆ setTest33816EngineConfiguration()

| void setTest33816EngineConfiguration | ( | ) |

set engine_type 103

Definition at line 448 of file custom_engine.cpp.

Referenced by applyEngineType().

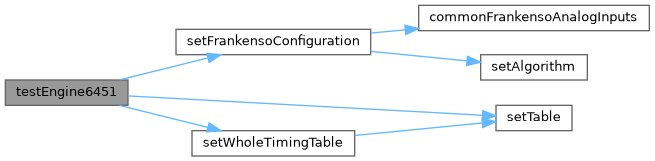

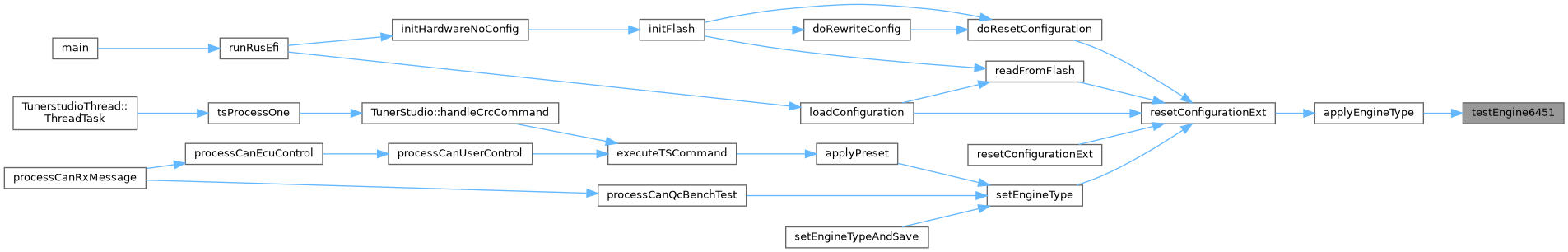

◆ testEngine6451()

| void testEngine6451 | ( | ) |

Definition at line 674 of file custom_engine.cpp.

Referenced by applyEngineType().

Variable Documentation

◆ eepdev_24xx

|

extern |

Referenced by setEepromTestConfiguration().

◆ i2cee

|

static |

https://www.onsemi.com/pdf/datasheet/cat24c32-d.pdf CAT24C32

Definition at line 217 of file custom_engine.cpp.

◆ ifile

|

static |

Definition at line 229 of file custom_engine.cpp.

Referenced by setEepromTestConfiguration().

◆ write_buf

|

static |

Definition at line 208 of file custom_engine.cpp.