Functions | |

| void | setLeftRightBanksNeedBetterName () |

| void | setDefaultBaseEngine () |

| void | setDefaultFuel () |

| void | setDefaultIgnition () |

| void | setDefaultCranking () |

| void | setGDIFueling () |

| void | setHpfpLobeProfileAngle (int lobes) |

| void | setGdiWallWetting () |

| void | setInline4 () |

| void | setDynoDefaults () |

| void | setupTLE9201 (Gpio controlPin, Gpio direction, Gpio disable, int dcIndex=0) |

| void | setupTLE9201IncludingStepper (Gpio controlPin, Gpio direction, Gpio disable, int dcIndex=0) |

| void | setPPSInputs (adc_channel_e pps1, adc_channel_e pps2) |

| void | setPPSCalibration (float primaryUp, float primaryDown, float secondaryUp, float secondaryDown) |

| void | setTPS1Inputs (adc_channel_e tps1, adc_channel_e tps2) |

| void | setTPS1Calibration (uint16_t tpsMin, uint16_t tpsMax) |

| void | setTPS1Calibration (uint16_t tpsMin, uint16_t tpsMax, uint16_t tps1SecondaryMin, uint16_t tps1SecondaryMax) |

| void | setCustomMap (float lowValue, float mapLowValueVoltage, float highValue, float mapHighValueVoltage) |

| void | setEtbPID (float p, float i, float d) |

| void | defaultsOrFixOnBurn () |

Function Documentation

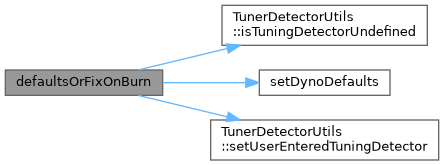

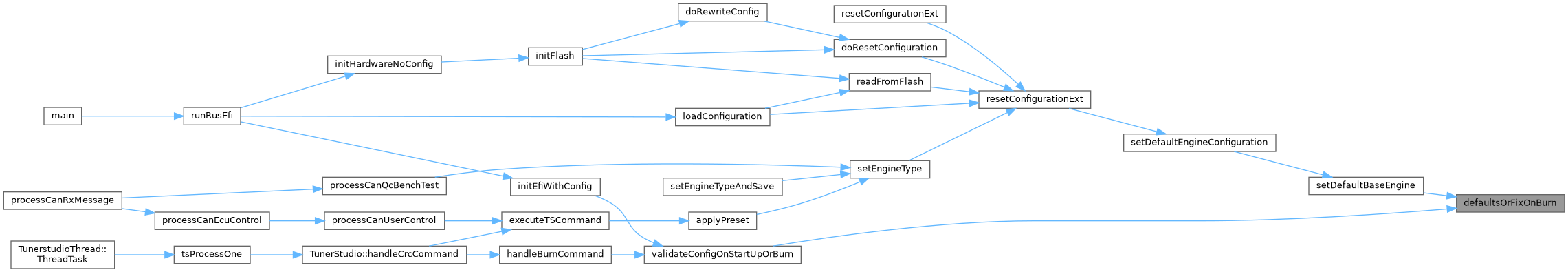

◆ defaultsOrFixOnBurn()

| void defaultsOrFixOnBurn | ( | ) |

Definition at line 129 of file default_base_engine.cpp.

Referenced by setDefaultBaseEngine(), and validateConfigOnStartUpOrBurn().

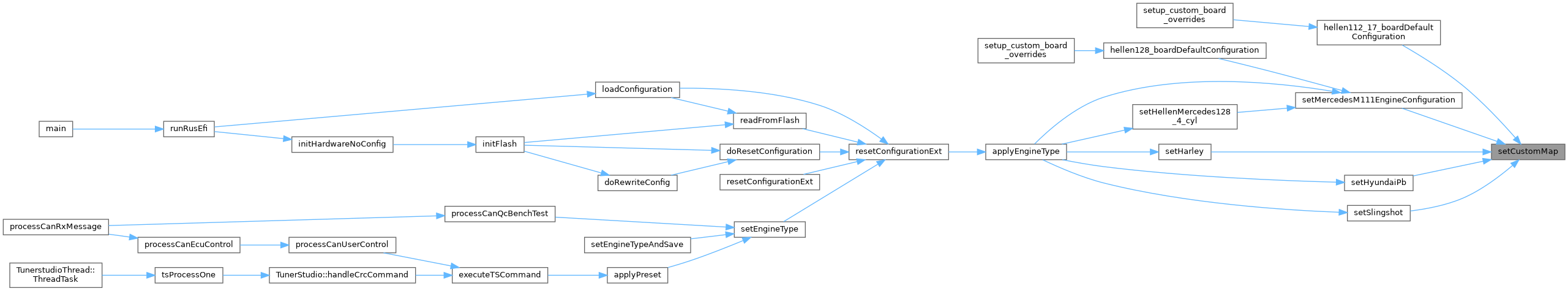

◆ setCustomMap()

| void setCustomMap | ( | float | lowValue, |

| float | mapLowValueVoltage, | ||

| float | highValue, | ||

| float | mapHighValueVoltage | ||

| ) |

Definition at line 470 of file default_base_engine.cpp.

Referenced by hellen112_17_boardDefaultConfiguration(), setHarley(), setHyundaiPb(), setMercedesM111EngineConfiguration(), and setSlingshot().

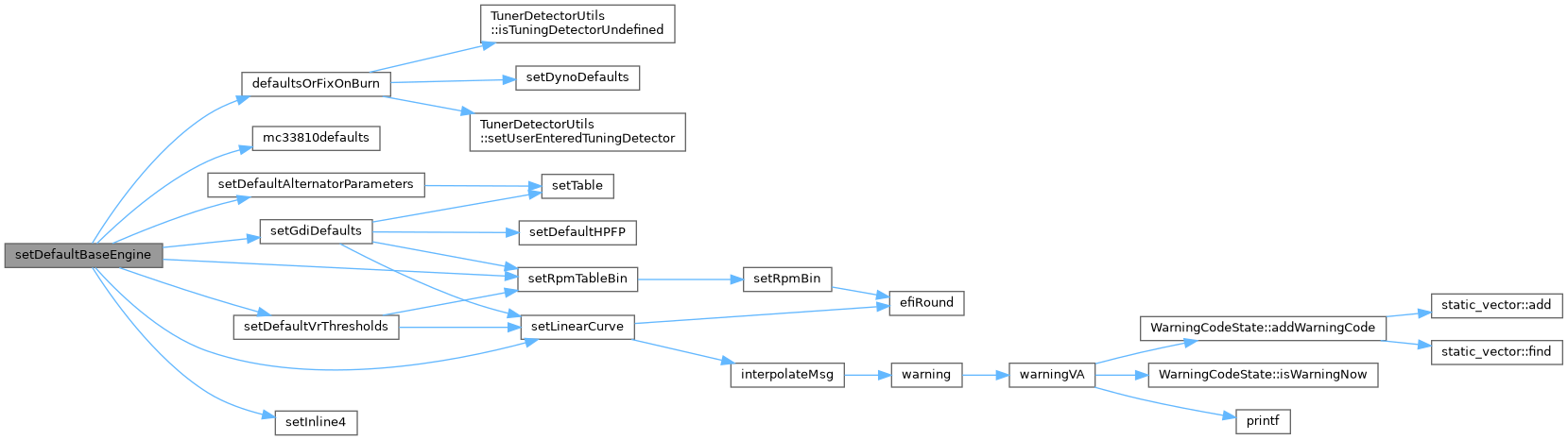

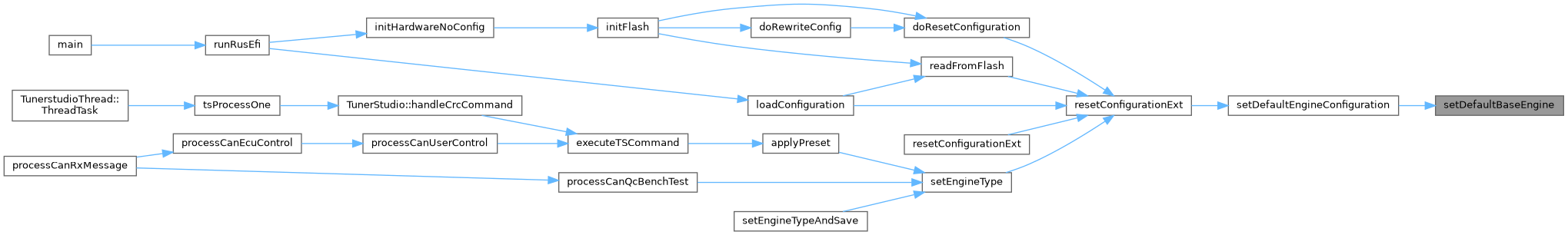

◆ setDefaultBaseEngine()

| void setDefaultBaseEngine | ( | ) |

Definition at line 170 of file default_base_engine.cpp.

Referenced by setDefaultEngineConfiguration().

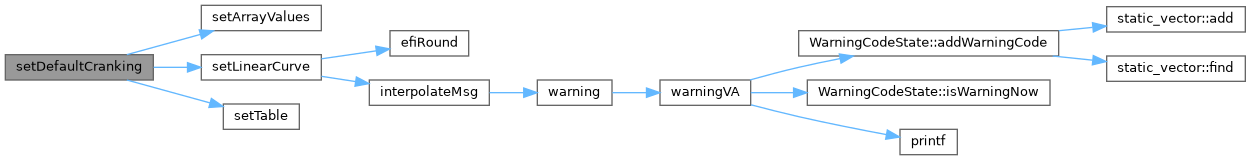

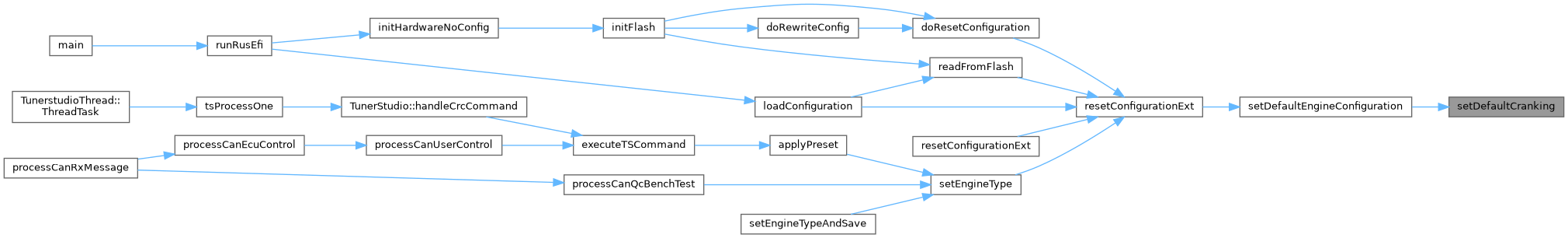

◆ setDefaultCranking()

| void setDefaultCranking | ( | ) |

Definition at line 6 of file default_cranking.cpp.

Referenced by setDefaultEngineConfiguration().

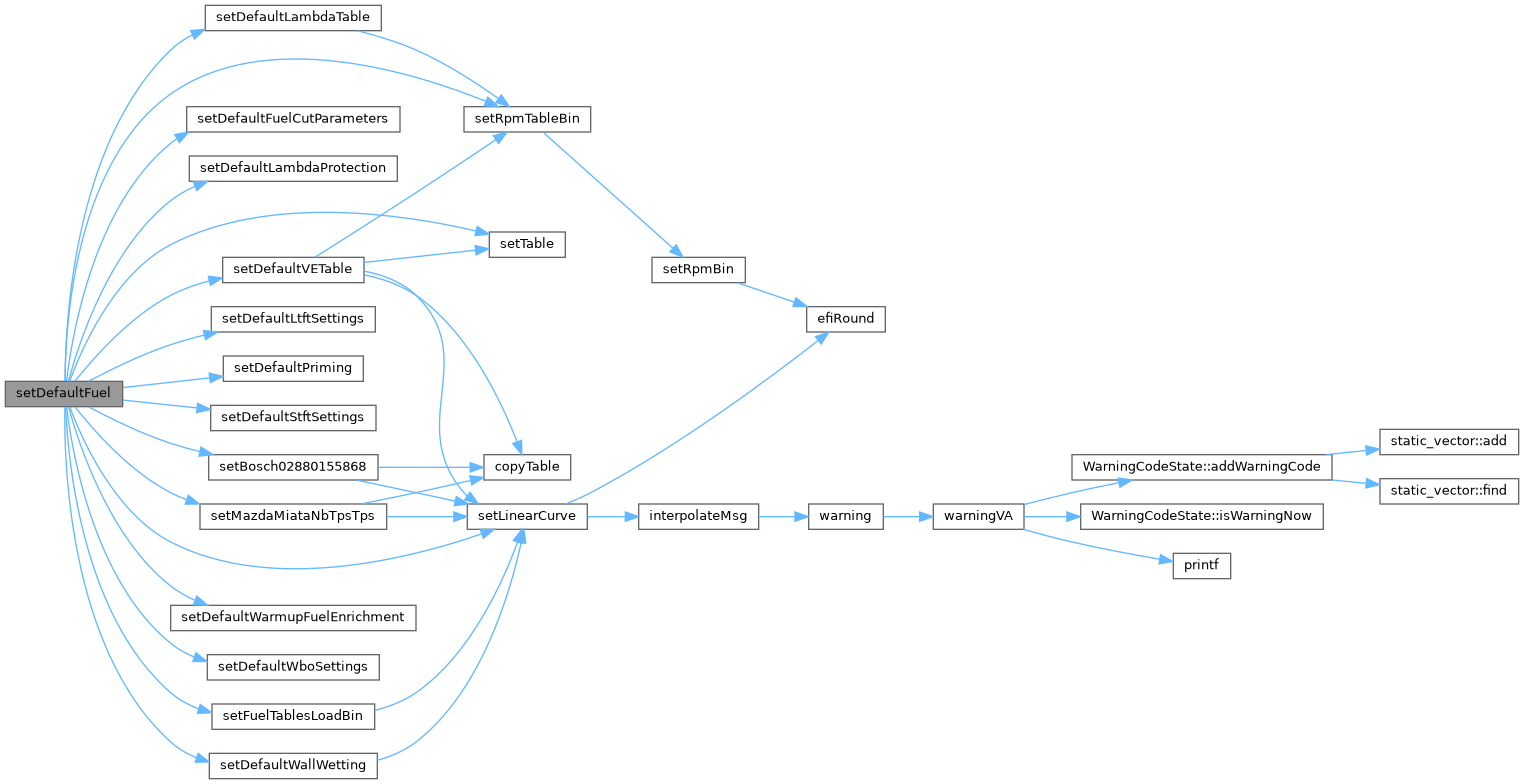

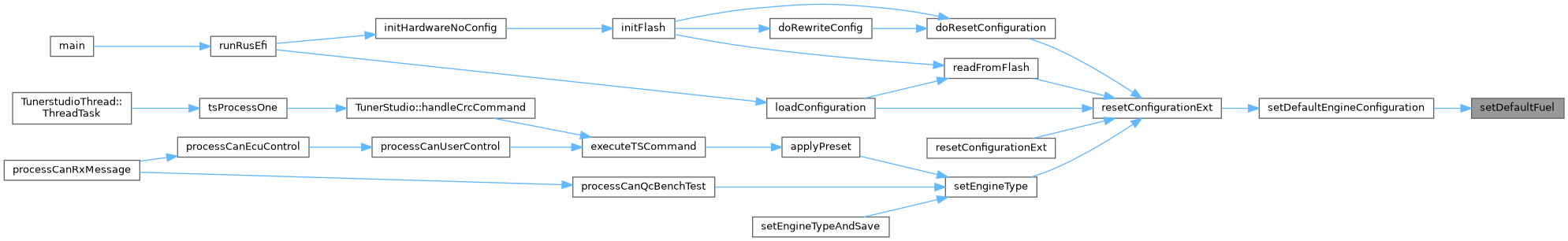

◆ setDefaultFuel()

| void setDefaultFuel | ( | ) |

By the way http://users.erols.com/srweiss/tableifc.htm has a LOT of data

Definition at line 314 of file default_fuel.cpp.

Referenced by setDefaultEngineConfiguration().

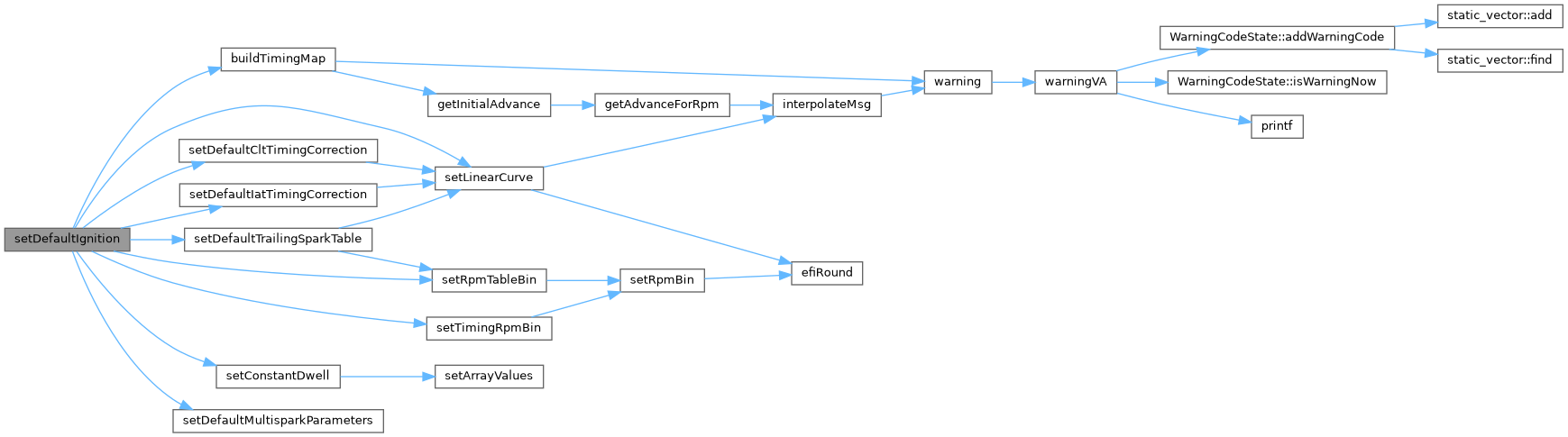

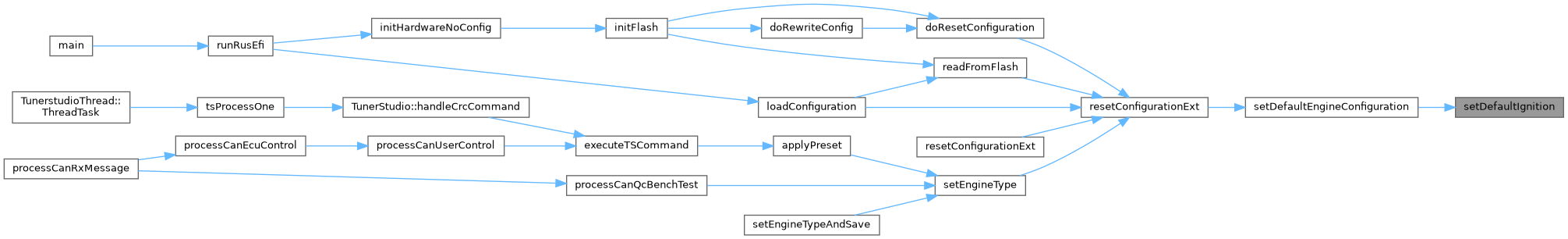

◆ setDefaultIgnition()

| void setDefaultIgnition | ( | ) |

Definition at line 101 of file default_ignition.cpp.

Referenced by setDefaultEngineConfiguration().

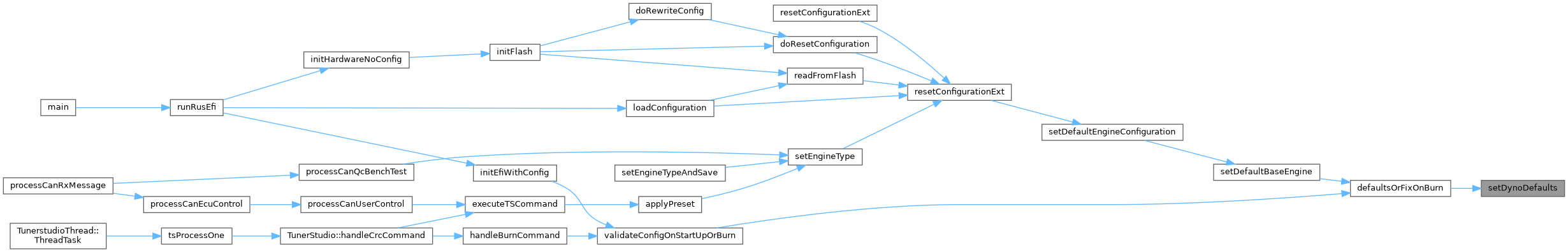

◆ setDynoDefaults()

| void setDynoDefaults | ( | ) |

Definition at line 108 of file default_base_engine.cpp.

Referenced by defaultsOrFixOnBurn().

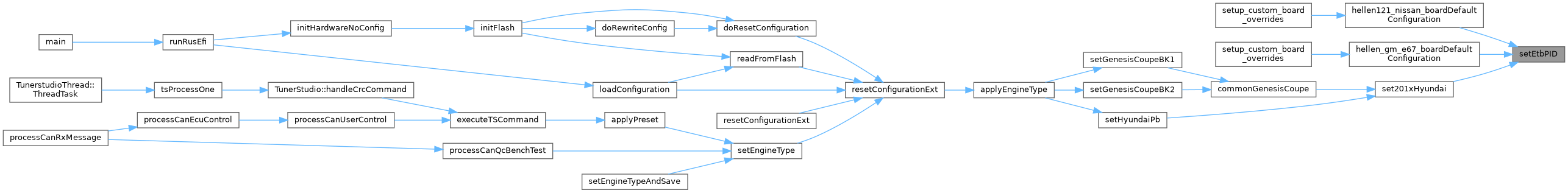

◆ setEtbPID()

Definition at line 485 of file default_base_engine.cpp.

Referenced by hellen121_nissan_boardDefaultConfiguration(), hellen_gm_e67_boardDefaultConfiguration(), and set201xHyundai().

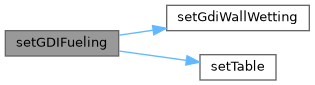

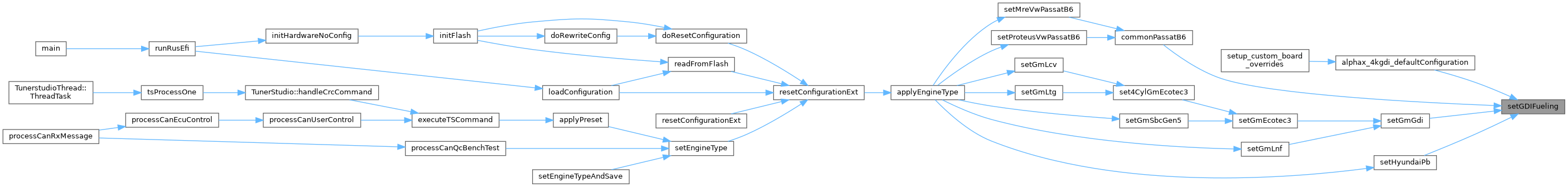

◆ setGDIFueling()

| void setGDIFueling | ( | ) |

Definition at line 70 of file default_base_engine.cpp.

Referenced by alphax_4kgdi_defaultConfiguration(), commonPassatB6(), setGmGdi(), and setHyundaiPb().

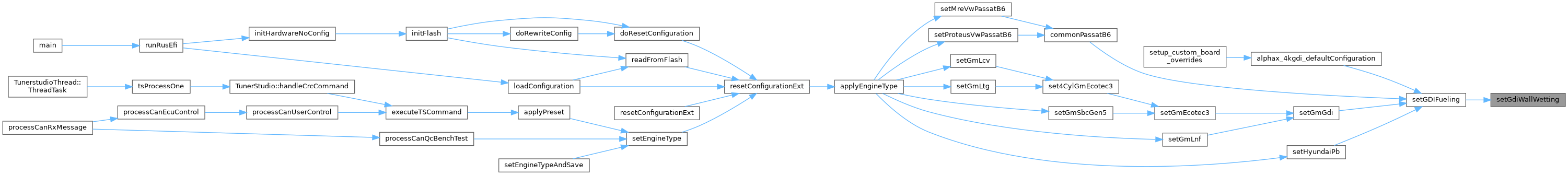

◆ setGdiWallWetting()

| void setGdiWallWetting | ( | ) |

Definition at line 245 of file default_fuel.cpp.

Referenced by setGDIFueling().

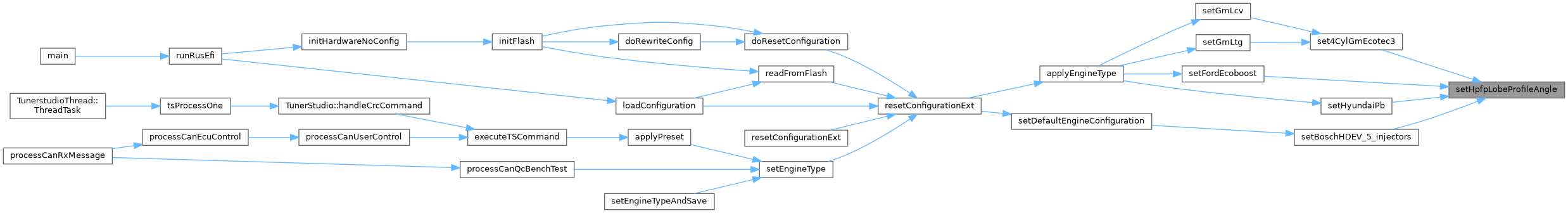

◆ setHpfpLobeProfileAngle()

| void setHpfpLobeProfileAngle | ( | int | lobes | ) |

Definition at line 22 of file default_base_engine.cpp.

Referenced by set4CylGmEcotec3(), setBoschHDEV_5_injectors(), setFordEcoboost(), and setHyundaiPb().

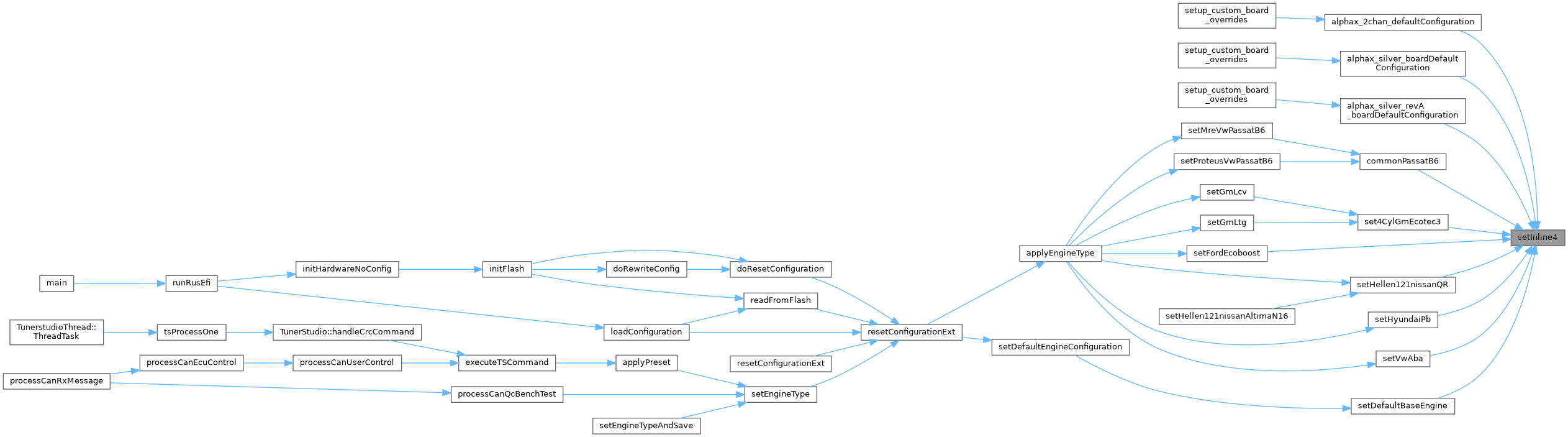

◆ setInline4()

| void setInline4 | ( | ) |

Definition at line 491 of file default_base_engine.cpp.

Referenced by alphax_2chan_defaultConfiguration(), alphax_silver_boardDefaultConfiguration(), alphax_silver_revA_boardDefaultConfiguration(), commonPassatB6(), set4CylGmEcotec3(), setDefaultBaseEngine(), setFordEcoboost(), setHellen121nissanQR(), setHyundaiPb(), and setVwAba().

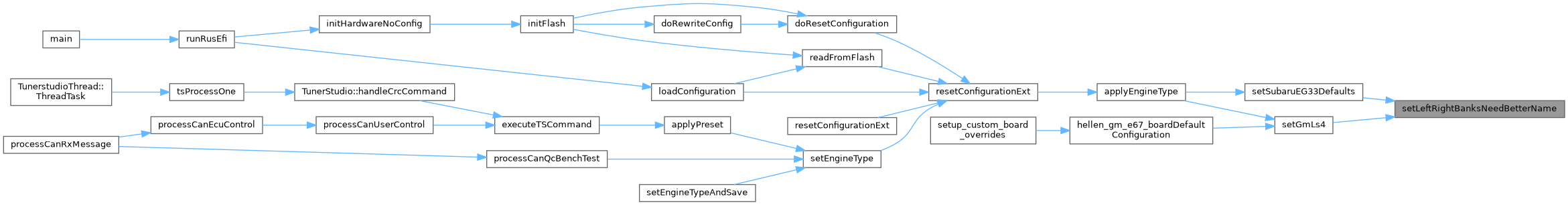

◆ setLeftRightBanksNeedBetterName()

| void setLeftRightBanksNeedBetterName | ( | ) |

file defaults.h

Definition at line 95 of file default_base_engine.cpp.

Referenced by setGmLs4(), and setSubaruEG33Defaults().

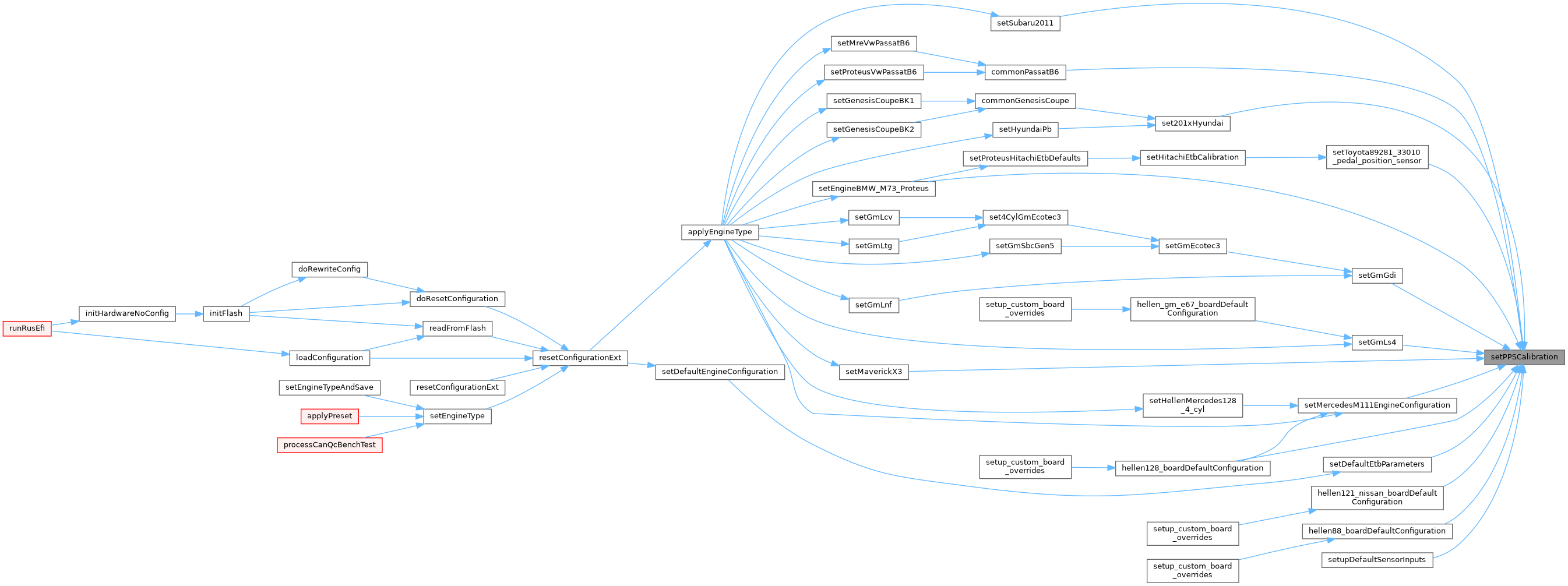

◆ setPPSCalibration()

| void setPPSCalibration | ( | float | primaryUp, |

| float | primaryDown, | ||

| float | secondaryUp, | ||

| float | secondaryDown | ||

| ) |

Definition at line 478 of file default_base_engine.cpp.

Referenced by commonPassatB6(), hellen121_nissan_boardDefaultConfiguration(), hellen128_boardDefaultConfiguration(), hellen88_boardDefaultConfiguration(), set201xHyundai(), setDefaultEtbParameters(), setEngineBMW_M73_Proteus(), setGmGdi(), setGmLs4(), setMaverickX3(), setMercedesM111EngineConfiguration(), setSubaru2011(), setToyota89281_33010_pedal_position_sensor(), and setupDefaultSensorInputs().

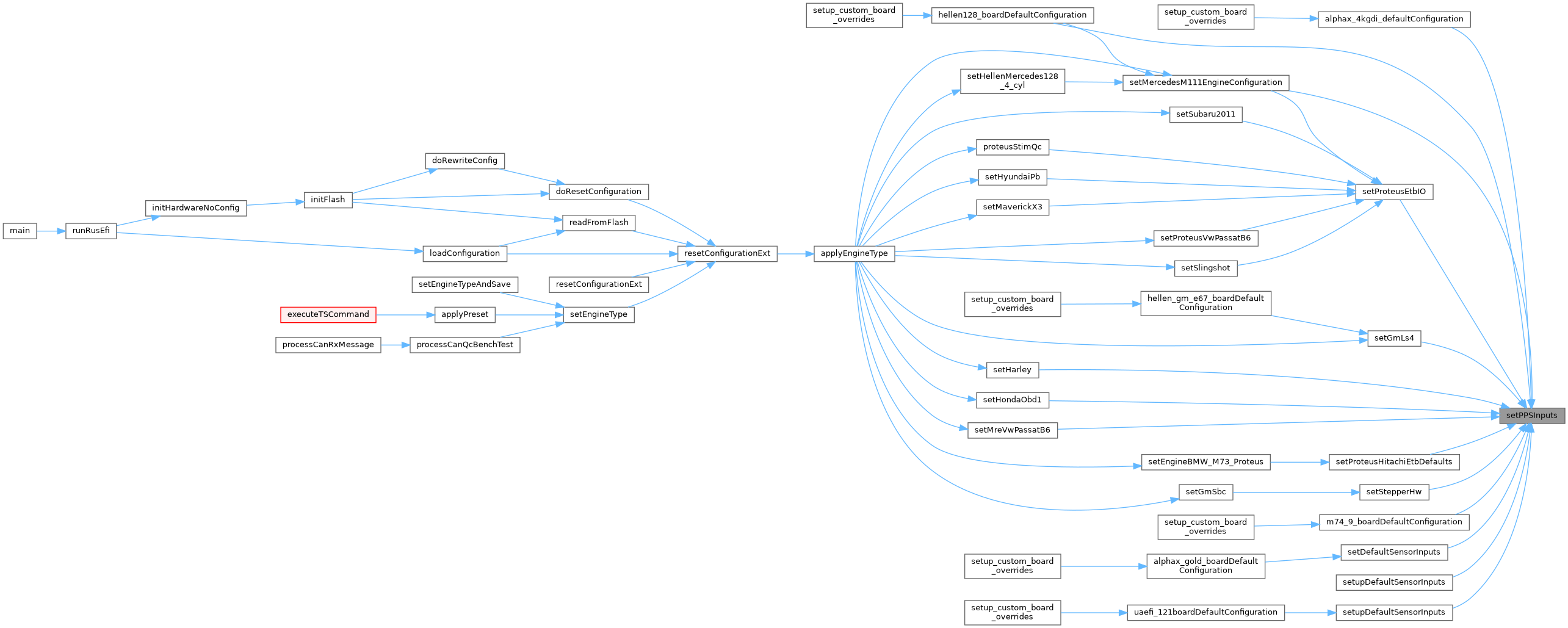

◆ setPPSInputs()

| void setPPSInputs | ( | adc_channel_e | pps1, |

| adc_channel_e | pps2 | ||

| ) |

Definition at line 447 of file default_base_engine.cpp.

Referenced by alphax_4kgdi_defaultConfiguration(), hellen128_boardDefaultConfiguration(), m74_9_boardDefaultConfiguration(), setDefaultSensorInputs(), setGmLs4(), setHarley(), setHondaObd1(), setMercedesM111EngineConfiguration(), setMreVwPassatB6(), setProteusEtbIO(), setProteusHitachiEtbDefaults(), setStepperHw(), setupDefaultSensorInputs(), and setupDefaultSensorInputs().

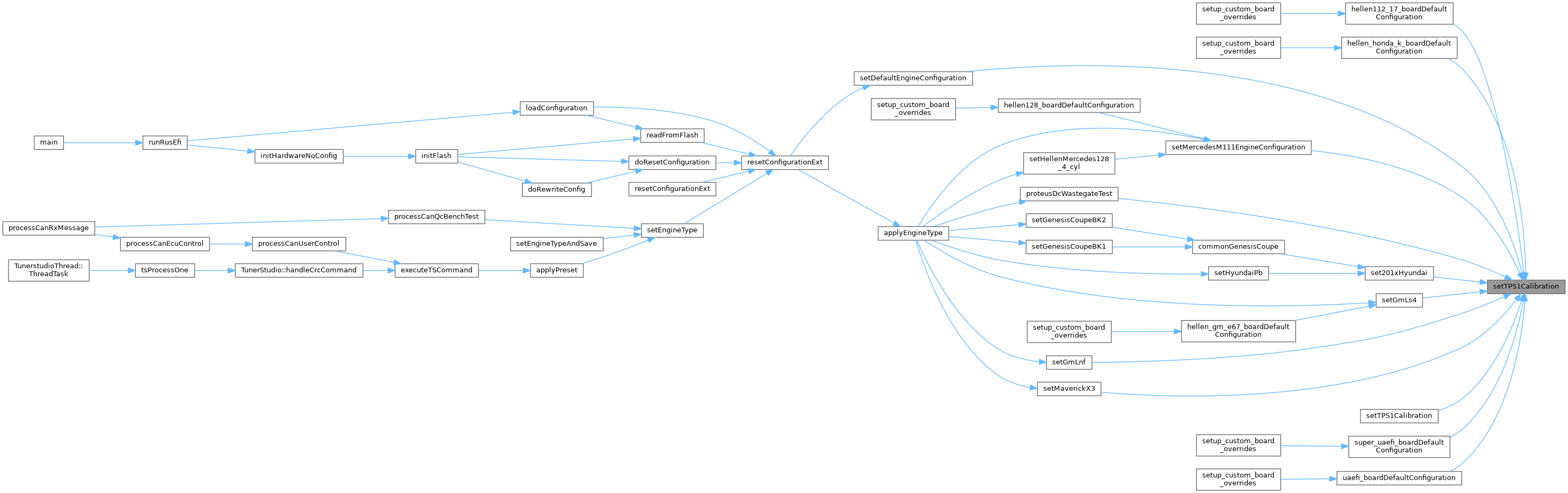

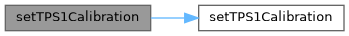

◆ setTPS1Calibration() [1/2]

| void setTPS1Calibration | ( | uint16_t | tpsMin, |

| uint16_t | tpsMax | ||

| ) |

Definition at line 457 of file default_base_engine.cpp.

Referenced by hellen112_17_boardDefaultConfiguration(), hellen_honda_k_boardDefaultConfiguration(), proteusDcWastegateTest(), set201xHyundai(), setDefaultEngineConfiguration(), setGmLnf(), setGmLs4(), setMaverickX3(), setMercedesM111EngineConfiguration(), setTPS1Calibration(), super_uaefi_boardDefaultConfiguration(), and uaefi_boardDefaultConfiguration().

◆ setTPS1Calibration() [2/2]

| void setTPS1Calibration | ( | uint16_t | tpsMin, |

| uint16_t | tpsMax, | ||

| uint16_t | tps1SecondaryMin, | ||

| uint16_t | tps1SecondaryMax | ||

| ) |

Definition at line 462 of file default_base_engine.cpp.

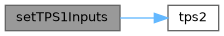

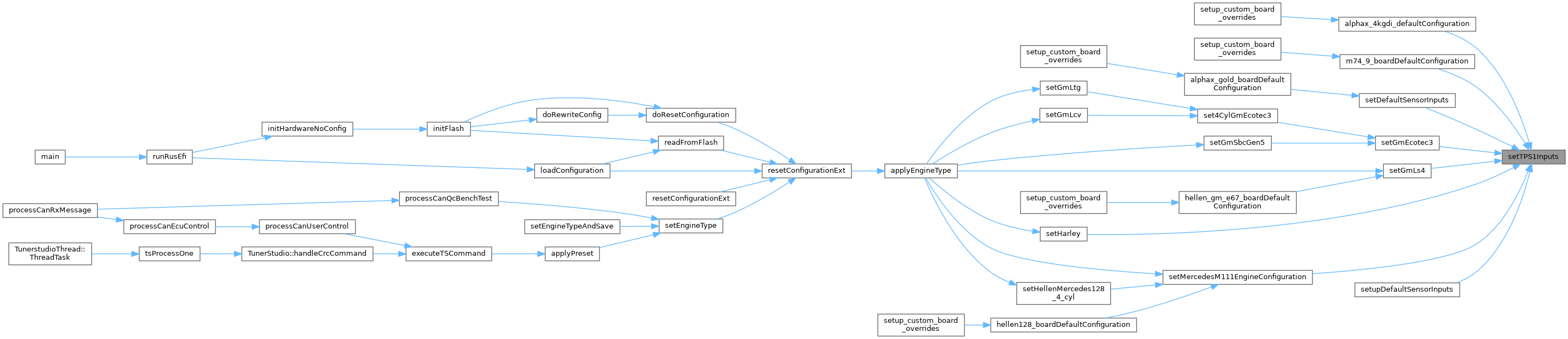

◆ setTPS1Inputs()

| void setTPS1Inputs | ( | adc_channel_e | tps1, |

| adc_channel_e | tps2 | ||

| ) |

Definition at line 452 of file default_base_engine.cpp.

Referenced by alphax_4kgdi_defaultConfiguration(), m74_9_boardDefaultConfiguration(), setDefaultSensorInputs(), setGmEcotec3(), setGmLs4(), setHarley(), setMercedesM111EngineConfiguration(), and setupDefaultSensorInputs().

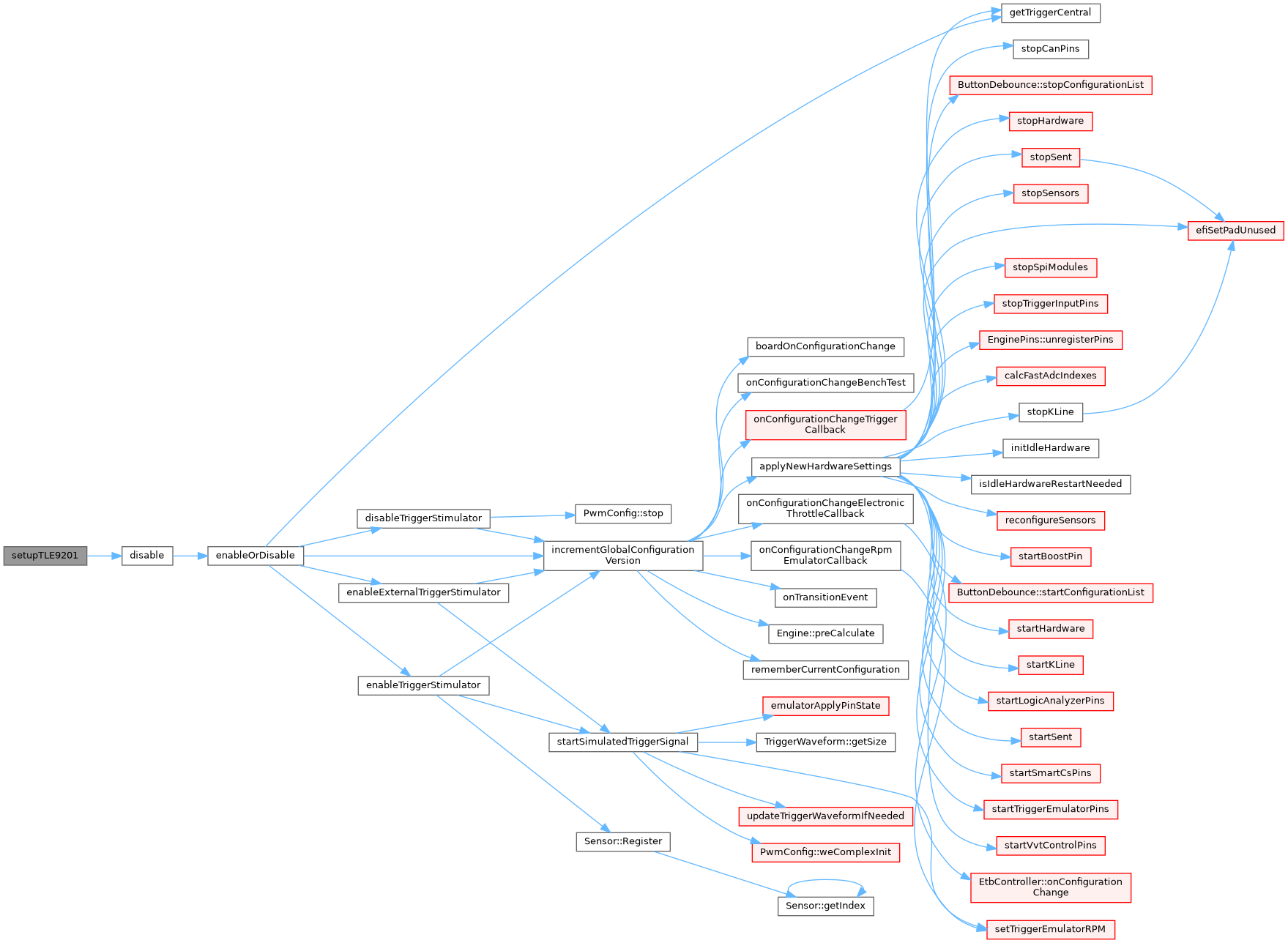

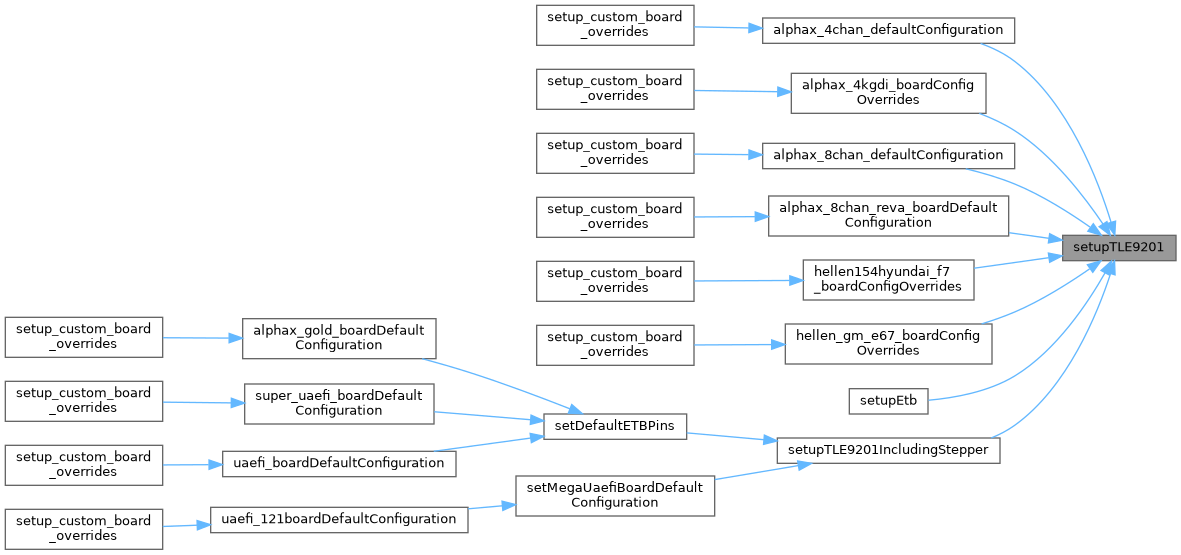

◆ setupTLE9201()

Definition at line 503 of file default_base_engine.cpp.

Referenced by alphax_4chan_defaultConfiguration(), alphax_4kgdi_boardConfigOverrides(), hellen154hyundai_f7_boardConfigOverrides(), hellen_gm_e67_boardConfigOverrides(), setupEtb(), and setupTLE9201IncludingStepper().

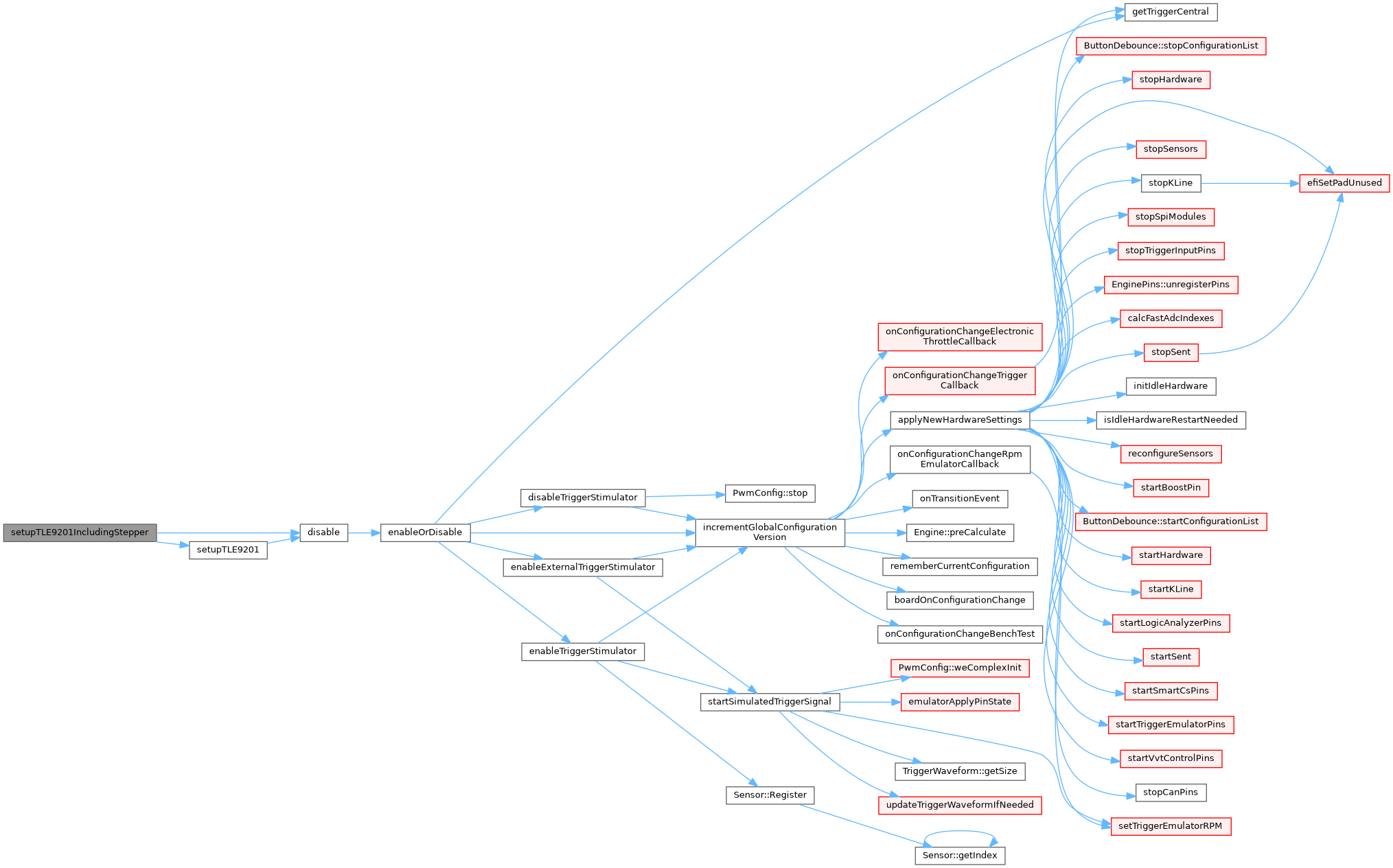

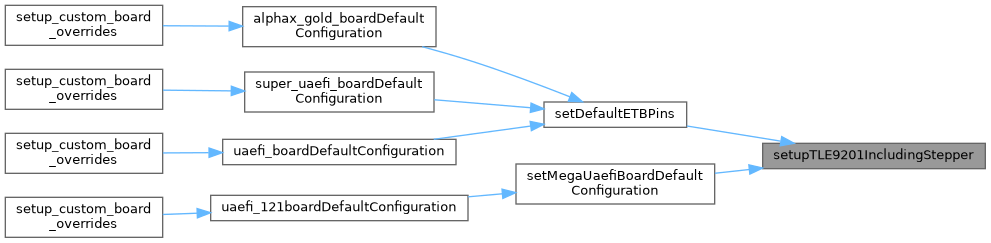

◆ setupTLE9201IncludingStepper()

| void setupTLE9201IncludingStepper | ( | Gpio | controlPin, |

| Gpio | direction, | ||

| Gpio | disable, | ||

| int | dcIndex = 0 |

||

| ) |

Definition at line 521 of file default_base_engine.cpp.

Referenced by set8chanDefaultETBPins(), setDefaultETBPins(), setMegaUaefiBoardDefaultConfiguration(), and setUaefiDefaultETBPins().